Position:Home » Product Info

Shunt Resistors' Features and Applications in Automotive Electronics

Writer:Microhm Page View:Date:2019-04-24

Shunt resistors are manufactured by using the technique of high-energy electron beam welding. With the large-area Cu terminal and high density CuMnNi, CuMnSn, NiCrAlSi or FeCrAl, the resistance value of less than 100μΩ,high current density and high pulse power are realized by using metal strips. The CuMnNi, CuMnSn, NiCrAlSi and FeCrAl materials can be punched into various shapes, offering the flexibility in design of resistors with the desired structure.

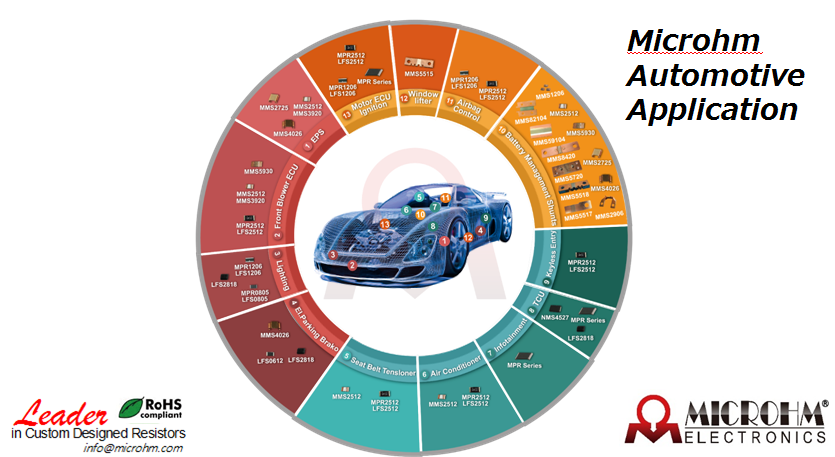

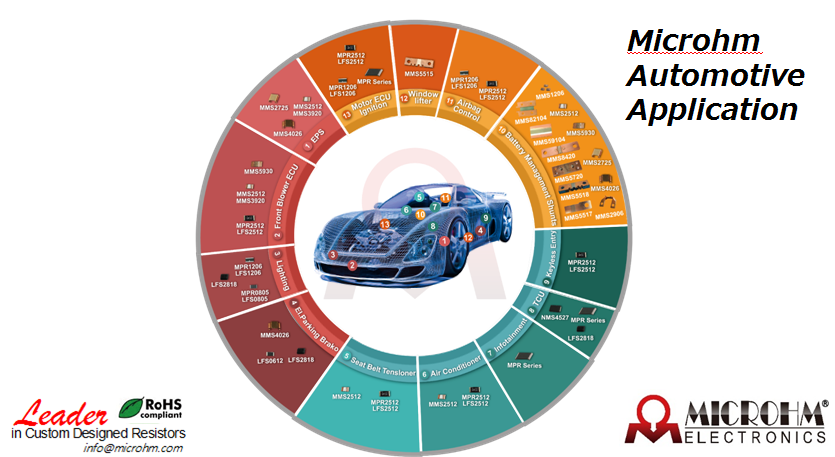

Due to all these features, shunt resistor is being an indispensible part of automotives. Microhm's MMS2725, MMS3920 and MMS4206 is used in EPS, MMS3920 is applied to climate control system converter. MMS2725 and MMS2512 is suitable for DC/DC converter and MMS8420 is very popular for battery management system and power electronics control.

Complete ideal resistors preventing from external interference is not exist in reality, while Microhm spare no efforts to minimize the external disturbance.

'

Microhm's high-energy electron beam welding technology is mature and verified by years of shunt resistor mass production. The weld seam is compact and flat, with strong mechanical strength, no additive and impurity. Benefiting from the metal composite material and punching, shunt resistor features low TCR, high long stability, ultra-low internal thermal resistance, low EMF against copper and low power dissipation. The resistance ranges from 100μΩ to 10mΩ normally. Tolerance include 1% and 5%. Power is up to 36W. Typical TCR is 50ppm.

Due to all these features, shunt resistor is being an indispensible part of automotives. Microhm's MMS2725, MMS3920 and MMS4206 is used in EPS, MMS3920 is applied to climate control system converter. MMS2725 and MMS2512 is suitable for DC/DC converter and MMS8420 is very popular for battery management system and power electronics control.

Complete ideal resistors preventing from external interference is not exist in reality, while Microhm spare no efforts to minimize the external disturbance.

'

Keywords:Shunt Resist

Latest News

- Resistor's role in measuring and correcting LED,,,

- Single through-hole resistors' characteristics ,,,

- Why shunt resistors for current sense applicati,,,

- Metal-film resistors with small size, high resi,,,

- 36W High-Current Shunt Resistors MMS8420,,,

- 1W Surface Mount Resistor MPR1206,,,

- An Overview of Microhm Electronics' Resistor Pr,,,

- More anti-sulfur resistors used in harsh envir,,,

- Resistance changes with temperature,,,

- 140W TO247 High Power Heatsinkable Resistor,,,

- MMS5930 is ideal for current sensing in industr,,,

- Shunt resistors selection for engineers' design,,,

- Considerations for choosing precision resistors,,,

- Ceramic Encased Cement Resistors NWH Series for,,,

- Resistors for Passive Balancing in Battery-Pow,,,

Hot Articles

- Microhm will take part in 10th Automotive World,,,

- Thanks for Visiting Microhm's Booth E5-5706 in ,,,

- Resistors in Short Supply: Blame Cars,,,

- New lunch: High Power Precision Shunt Resistor,,,,

- How to Test a Resistor,,,

- Innovative Technology, Future Electric: Electri,,,

- What is Precision Resistors?,,,

- SMD Resistors Sizes and Packages,,,

- The Construction and Features of Metal Film Res,,,

- What is a TO-220 Resisor?,,,

- Hot Selling Products: Precision Shunt Resistors,,,

- How to Calculate the Equivalent Resistance Valu,,,

- What is a Fixed Resistor?,,,

- Resistors in LED Circuits,,,

- Resistors Types and Materials Overview,,,

Resistance applications

- Urbanization Development Bringing the Transform,,,

- Difference Between High Precision Resistors and,,,

- The Measurement Accuracy of Automotive Shunt is,,,

- Miniature future for passive electronic compone,,,

- Surface Mount Resistor's Size and Package ,,,

- Shunt Resistor MMS8420 for High Current Stable ,,,

- Carbon Film Resistors' Features and Application,,,

- The Main Application for High Precision and Low,,,

- Heater Blower Motor Resistor in Air Conditioner,,,

- The Four Important Functions of Alloy Resistors,,,

- Select the Right Resistor for Harmonic Filterin,,,

- BMS for New Energy Vehicle,,,

- Industrial Roberts Applied to Solar Photovoltai,,,

- Why Zero-Ohm Resistors?,,,

- Precision Resistors' Construction and TCR,,,