Position:Home » Industry News

More anti-sulfur resistors used in harsh environments

Writer:Microhm Page View:Date:2020-01-20

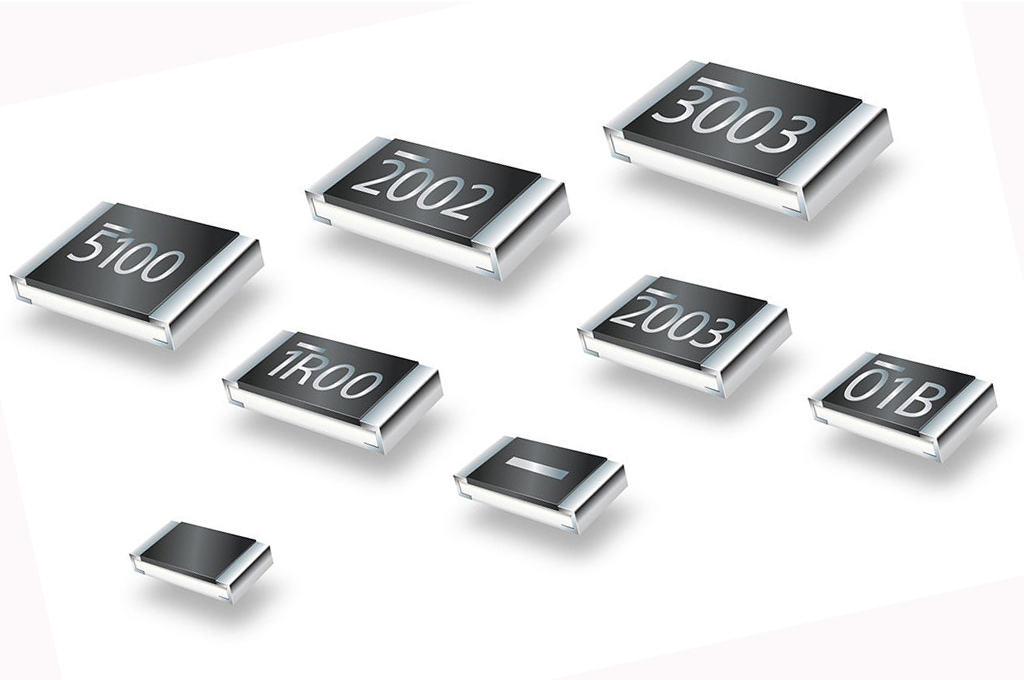

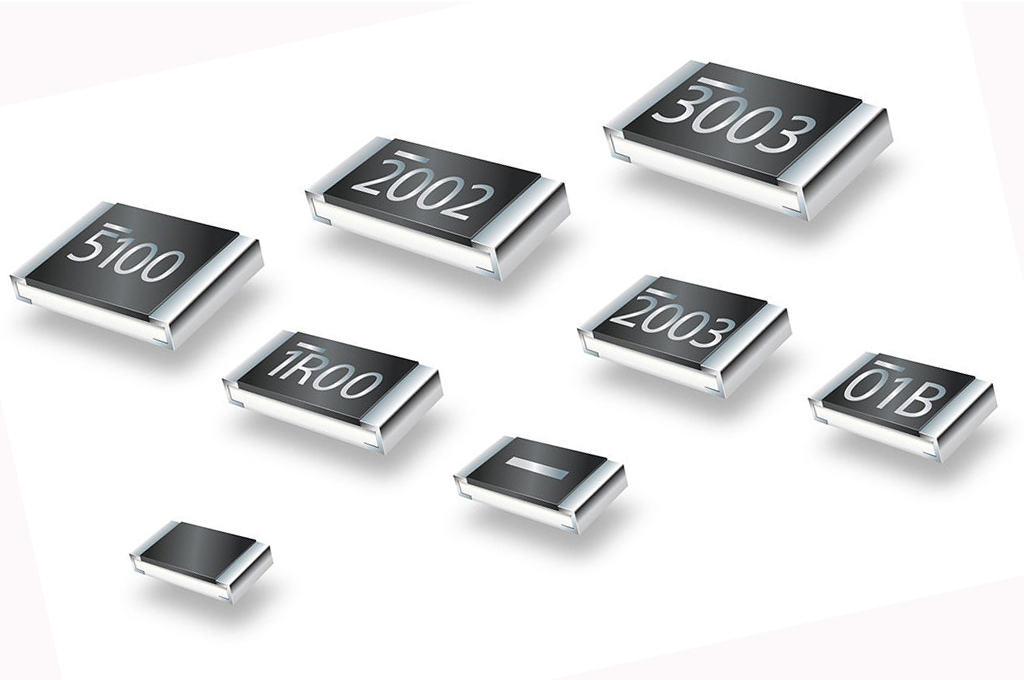

Electronic components, including resistors, often have to operate in harsh, challenging environments. Given the fluctuating natures of climates all over the globe, the task that requires components to operate in high humidity, extreme dryness and incredibly moist environments comes as no surprise. Besides moisture, heat, sulfur is also endange the resistors performance. What may come as a surprise is that thick-film SMDs, the resistor type most often used in today’s designs, are actually quite resilient to this common threat, take Microhm Electronics' NBS series for instance. It is their susceptibility to sulfur that takes many designers by surprise.

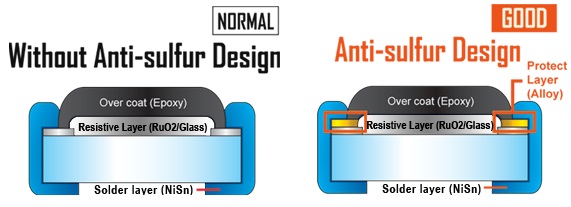

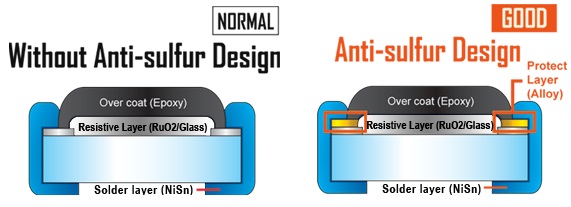

Sulfur is present in many common lubricants, and is also present in components made of rubber, including gaskets, seals and grommets. Thick-film chip resistors, in particular, use a combination of silver and palladium in their inner terminations, with silver comprising more and more of the mix because of its lower cost. Sulfur and silver are reactive to each other, forming silver sulfide. The intrusion of the sulfur into the resistor generally occurs in the tiny gap that is present on the border between the outer electrode, which is the electrical conduit between the device and the PCB, and the protective coating that protects the rest of the component. Once inside, the sulfur can readily react with the silver of the inner electrode, changing it into silver sulfide.

Over the course of an electronic product’s lifetime, this process of sulfuration causes considerable degradation. It is the source of added resistance, way beyond the resistor’s expressed tolerance. Another factor to take into account is that the silver sulfide formed in this process takes up more physical room than the silver that it replaces. The result is the occurrence of cracks, leaving a void through which more sulfur can seep in. The outcome can be that all the silver in the contact is engulfed, taking the resistor entirely out of the circuit, and leaving an open circuit.

Solutions to this problem are not inexpensive. They include going back to using more palladium and less silver, and even adding a tiny coating of gold, because gold does not react with sulfur. This is the solution effect by Microhm Electronics NBS series thick-film SMDs which has gold, providing protection in a sulfurous environment. The datasheet reveals that this component is available in a variety of resistance value tolerances and power ratings.

Fortunately, thin-film resistors, which are largely immune to problems involving sulfur, have become progressively cheaper to produce. The two main types employ resistive elements composed of tantalum nitride and nickel chromium, with the former also being able to resist problems with moisture. Their resistance to problems with sulfur is based on their inner electrode, which is comprised largely of nichrome, instead of silver. Thin-film resistors enjoy other advantages over their thick-film counterparts. These include lower stray induction and capacitance, better TCRs and they can be more efficaciously miniaturized.

Sulfur is present in many common lubricants, and is also present in components made of rubber, including gaskets, seals and grommets. Thick-film chip resistors, in particular, use a combination of silver and palladium in their inner terminations, with silver comprising more and more of the mix because of its lower cost. Sulfur and silver are reactive to each other, forming silver sulfide. The intrusion of the sulfur into the resistor generally occurs in the tiny gap that is present on the border between the outer electrode, which is the electrical conduit between the device and the PCB, and the protective coating that protects the rest of the component. Once inside, the sulfur can readily react with the silver of the inner electrode, changing it into silver sulfide.

Over the course of an electronic product’s lifetime, this process of sulfuration causes considerable degradation. It is the source of added resistance, way beyond the resistor’s expressed tolerance. Another factor to take into account is that the silver sulfide formed in this process takes up more physical room than the silver that it replaces. The result is the occurrence of cracks, leaving a void through which more sulfur can seep in. The outcome can be that all the silver in the contact is engulfed, taking the resistor entirely out of the circuit, and leaving an open circuit.

Solutions to this problem are not inexpensive. They include going back to using more palladium and less silver, and even adding a tiny coating of gold, because gold does not react with sulfur. This is the solution effect by Microhm Electronics NBS series thick-film SMDs which has gold, providing protection in a sulfurous environment. The datasheet reveals that this component is available in a variety of resistance value tolerances and power ratings.

Fortunately, thin-film resistors, which are largely immune to problems involving sulfur, have become progressively cheaper to produce. The two main types employ resistive elements composed of tantalum nitride and nickel chromium, with the former also being able to resist problems with moisture. Their resistance to problems with sulfur is based on their inner electrode, which is comprised largely of nichrome, instead of silver. Thin-film resistors enjoy other advantages over their thick-film counterparts. These include lower stray induction and capacitance, better TCRs and they can be more efficaciously miniaturized.

Latest News

- The 5G Materials Battle: Sub-6 GHz vs mmWave,,,

- GREETINGS TO THE YEAR OF TIGER 2022,,,

- Electronic Resistor supply chain 2021 under COV,,,

- New Year Greetings,,,

- SEASON'S GREETINGS,,,

- Microhm electronic high precision metal foil re,,,

- Resistor's role in measuring and correcting LED,,,

- Single through-hole resistors' characteristics ,,,

- Why shunt resistors for current sense applicati,,,

- Metal-film resistors with small size, high resi,,,

- 36W High-Current Shunt Resistors MMS8420,,,

- 1W Surface Mount Resistor MPR1206,,,

- An Overview of Microhm Electronics' Resistor Pr,,,

- More anti-sulfur resistors used in harsh envir,,,

- Resistance changes with temperature,,,

Hot Articles

- Microhm will take part in 10th Automotive World,,,

- Thanks for Visiting Microhm's Booth E5-5706 in ,,,

- Resistors in Short Supply: Blame Cars,,,

- SMD Resistors Sizes and Packages,,,

- New lunch: High Power Precision Shunt Resistor,,,,

- How to Test a Resistor,,,

- Innovative Technology, Future Electric: Electri,,,

- What is Precision Resistors?,,,

- The Construction and Features of Metal Film Res,,,

- What is a TO-220 Resisor?,,,

- Hot Selling Products: Precision Shunt Resistors,,,

- How to Calculate the Equivalent Resistance Valu,,,

- What is a Fixed Resistor?,,,

- Resistors in LED Circuits,,,

- Resistors Types and Materials Overview,,,

Resistance applications

- Shunt Resistors' Function and Characteristics,,,

- Surface Mount Resistor's Advantages Manufacture,,,

- What is the Role of the Brake Resistor in the I,,,

- Method for Detecting DC Resistance and Insulati,,,

- Precision Shunts Using Copper-Manganese Alloy t,,,

- Wirewound Resistors Features,,,

- Resistance Measurement for Microhm Electronics',,,

- Power Resistor for Marine Application,,,

- Current Limiting Resistor and Pull-Up Resistors,,,

- Resistor's Rated Power Judgment and Calculation,,,

- Denmark Spends $30 Billion to Develop Renewable,,,

- Resistor solutions within inverter applications,,,

- Renewable Energy Company PacifiCorp and Vestas ,,,

- Why is the Resistor Always Easy to Burn in the ,,,

- High Power Resistor NLR Series,,,