Position:Home » Technical Articles

The Importance of Resistors in Overcurrent Protection

Writer:Microhm Page View:Date:2019-10-31

The key advantage of designing an SMPS with higher switching frequencies is to reduce the size of passive components and in turn increase the overall power density. One downside is that this increased power density multiplies the potential for damage in the event of an overcurrent event. Overcurrent events are an ever-present risk for SMPSs. Among other problems, overcurrent spikes can cause false triggering due to external parasitic inductance from the source pc board trace.

While rapid overcurrent protection (OCP) is important for SMPSs using traditional MOSFETs, it’s even more vital for eGaN HEMTs because:

For the same blocking voltage and on-state resistance, the eGaN HEMT area is much smaller, making it much harder to dissipate the heat build-up during an overcurrent event. Overcurrent must be detected while the eGaN HEMT is operating in the linear region, otherwise the device rapidly enters saturation causing excessive power dissipation and damage.

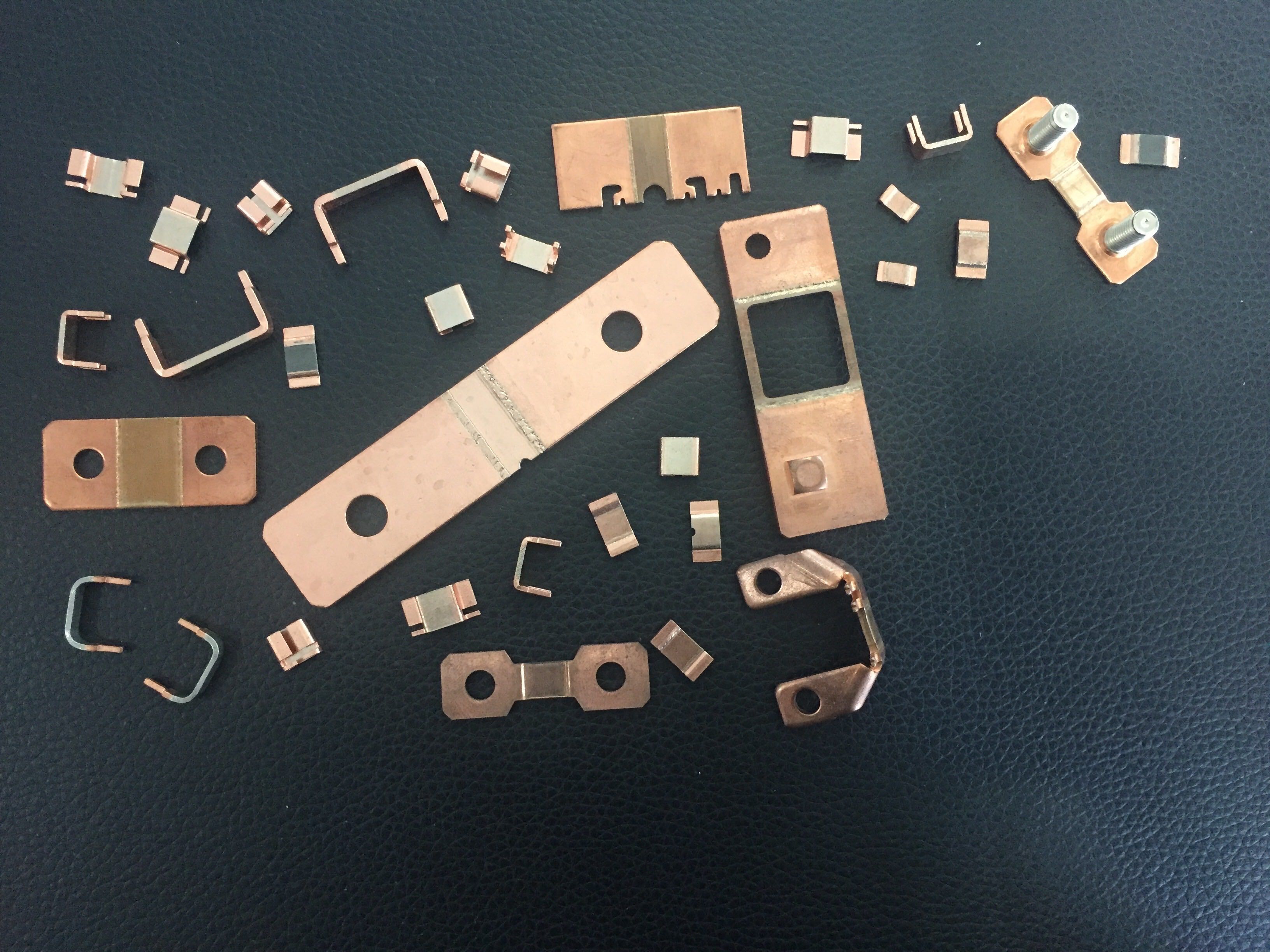

A conventional approach to OCP is to use a current sense transformer, shunt resistors, such as Microhm's MMS8420, MMS5930, or de-saturation detection circuits (Table). Unfortunately, these can adversely affect system performance by increasing parasitic inductances and resistances in the power loop, which in turn necessitate a reduction in slew rate and a resultant increase in power dissipation. Moreover, discrete devices such as sense transformers or shunt resistors add cost and take up board real estate.

An alternative approach to OCP is to sense the drain-source voltage (VDS) of the GaN FET using a current sensing element, a level shifter to report the signal to the controller, and a detection circuit. This method has the advantage of not generating the parasitic inductances and resistances that impinge on circuit performance, but it does lack accuracy primarily due to the large temperature coefficient of GaN.

A third option is to select an integrated eGaN power stage that includes an integrated OCP function. This eliminates the disadvantages of the two approaches described above. TI’s LMG3411 is an example of a product that includes this feature. The LMG3411’s protection circuit can turn off the eGaN HEMTS in less than 100 ns should an overcurrent be detected. When the PWM input returns to low on the next cycle, the output fault signal clears. This allows the eGaN HEMT to turn on normally on the next cycle, minimizing disruption at the output.

| OCP Option | OCP Performance | System Impact | Required Component | Area/Cost |

|---|---|---|---|---|

| Shunt Resistor | + Low tolerance resistors can provide good accuracy | - High power loop inductance and power losses | - Sense resistor, detection circuit, level shifter | - Medium/Medium |

| Current Transformer | + 0.1% linearity | - High power loop inductance, and it does not protect at high duty cycles | - Current transformer, detection circuit | - Large/High |

| VDS Sensing | - Process variations of FETs and large RDSON tempco | + None | - Detection circuit, level shifter | - Medium/Medium |

| Integrated OCP | + <100 ns response time | + None | - Level shifter | + No external components |

The increasing demand for high energy density SMPSs for applications such as solar inverters and server farms, combined with decreasing cost per device, has made eGaN HEMTs an attractive option for a greater range of power supply designs. While designing with eGaN HEMTs can be tricky, the introduction of eGaN HEMT power stages that integrate the gate driver(s) with the power transistor(s) has made it much easier for SMPS designers to incorporate the technology into their next high power density design.

Keywords:

Latest News

- Resistor's role in measuring and correcting LED,,,

- Single through-hole resistors' characteristics ,,,

- Why shunt resistors for current sense applicati,,,

- Metal-film resistors with small size, high resi,,,

- 36W High-Current Shunt Resistors MMS8420,,,

- 1W Surface Mount Resistor MPR1206,,,

- An Overview of Microhm Electronics' Resistor Pr,,,

- More anti-sulfur resistors used in harsh envir,,,

- Resistance changes with temperature,,,

- 140W TO247 High Power Heatsinkable Resistor,,,

- MMS5930 is ideal for current sensing in industr,,,

- Shunt resistors selection for engineers' design,,,

- Considerations for choosing precision resistors,,,

- Ceramic Encased Cement Resistors NWH Series for,,,

- Resistors for Passive Balancing in Battery-Pow,,,

Hot Articles

- Microhm will take part in 10th Automotive World,,,

- Thanks for Visiting Microhm's Booth E5-5706 in ,,,

- Resistors in Short Supply: Blame Cars,,,

- New lunch: High Power Precision Shunt Resistor,,,,

- How to Test a Resistor,,,

- Innovative Technology, Future Electric: Electri,,,

- What is Precision Resistors?,,,

- SMD Resistors Sizes and Packages,,,

- The Construction and Features of Metal Film Res,,,

- What is a TO-220 Resisor?,,,

- Hot Selling Products: Precision Shunt Resistors,,,

- How to Calculate the Equivalent Resistance Valu,,,

- What is a Fixed Resistor?,,,

- Resistors in LED Circuits,,,

- Resistors Types and Materials Overview,,,

Resistance applications

- The Four Important Functions of Alloy Resistors,,,

- The Main Application for High Precision and Low,,,

- BMS for New Energy Vehicle,,,

- Why Zero-Ohm Resistors?,,,

- Urbanization Development Bringing the Transform,,,

- The Measurement Accuracy of Automotive Shunt is,,,

- Difference Between High Precision Resistors and,,,

- Miniature future for passive electronic compone,,,

- Heater Blower Motor Resistor in Air Conditioner,,,

- Precision Resistors' Construction and TCR,,,

- Carbon Film Resistors' Features and Application,,,

- Surface Mount Resistor's Size and Package ,,,

- Shunt Resistor MMS8420 for High Current Stable ,,,

- Industrial Roberts Applied to Solar Photovoltai,,,

- Select the Right Resistor for Harmonic Filterin,,,