Position:Home » Technical Articles

How to Produce Precision Chip Resistors 2512 ?

Writer:Microhm Page View:Date:2019-04-10

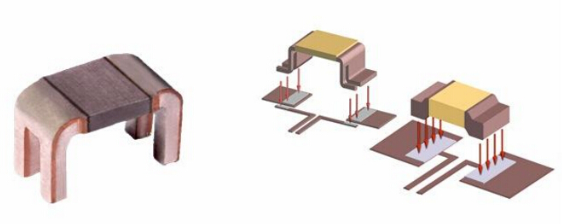

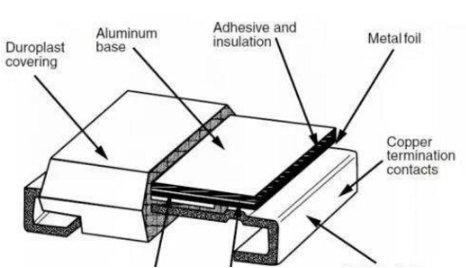

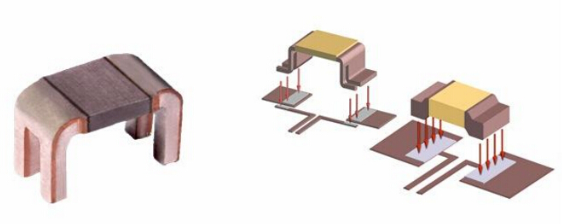

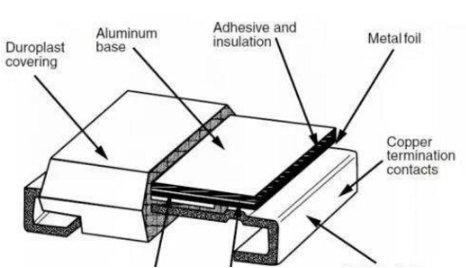

The precision chip resistor adopts the manganese-copper strip as the raw material. It is relatively complex to manufacture the resistor of the package size 2512 within ±1% tolerance. First of all, the manganese-copper strip is stamped into the required resistance pattern by precision stamping. The target resistance value is set, correcting the center value according to the upper and lower limits of the target resistance value so as to ensure that all products are controlled within the upper limit of the specification.

To modify the center value is to intentionally adjust the target center value below the actual center value so as to ensure that the printed alloy pattern sheet resistivity must not exceed the target upper limit. In the practical stamping process, the actual resistance value should be measured after each batch of graphics chips are impacted. Once it is found that there is an out-of-range resistance values, different punches or different batches of strips are replaced to meet the central value range of the target resistance value. Manganese-copper strip is only one type of resistance material. Resistance manufacturers can also use other suitable alloy materials to make precision chip resistors.

Precision chip resistor adopts resistance tester and special tool to measure resistance value.

According to the level of stamping process, the resistance graphics whose resistance value is less than the lower limit of the target are divided into N groups. Chemical etching solution for resistive adjustment needs to be prepared before resistive adjustment, adding a proper amount of tap water to the tank body 3, heating it to 30-50°C with a heater, adding etching salt with a mass ratio of 5%-10% and a strong acid configuration with a volume ratio of 1% - 5% to form the chemical liquid 1.

The precision chip resistor is made by adding 5% potassium bisulfate compound salt, opening the gas pump cycle, dissolving the etched salt completely, then adding 5% sulfuric acid in volume ratio. When the composition of the chemical liquid is uniform, the chemical liquid 1 can be put into production when the liquid level is stable. The volume of the chemical liquid 1 accounts for 80% of the total volume of the tank. The bath body may use a common plating PP bath, such as acid-resistant, alkali-resistant, aging-resistant, and high-temperature-resistant body, and a general electroplating PP bath shall be used for the heater. The heater shall be acid-resistant, alkali-resistant and leakage-proof. The present embodiment adopts a ferrolon heater for electroplating purpose.

To modify the center value is to intentionally adjust the target center value below the actual center value so as to ensure that the printed alloy pattern sheet resistivity must not exceed the target upper limit. In the practical stamping process, the actual resistance value should be measured after each batch of graphics chips are impacted. Once it is found that there is an out-of-range resistance values, different punches or different batches of strips are replaced to meet the central value range of the target resistance value. Manganese-copper strip is only one type of resistance material. Resistance manufacturers can also use other suitable alloy materials to make precision chip resistors.

Precision chip resistor adopts resistance tester and special tool to measure resistance value.

According to the level of stamping process, the resistance graphics whose resistance value is less than the lower limit of the target are divided into N groups. Chemical etching solution for resistive adjustment needs to be prepared before resistive adjustment, adding a proper amount of tap water to the tank body 3, heating it to 30-50°C with a heater, adding etching salt with a mass ratio of 5%-10% and a strong acid configuration with a volume ratio of 1% - 5% to form the chemical liquid 1.

The precision chip resistor is made by adding 5% potassium bisulfate compound salt, opening the gas pump cycle, dissolving the etched salt completely, then adding 5% sulfuric acid in volume ratio. When the composition of the chemical liquid is uniform, the chemical liquid 1 can be put into production when the liquid level is stable. The volume of the chemical liquid 1 accounts for 80% of the total volume of the tank. The bath body may use a common plating PP bath, such as acid-resistant, alkali-resistant, aging-resistant, and high-temperature-resistant body, and a general electroplating PP bath shall be used for the heater. The heater shall be acid-resistant, alkali-resistant and leakage-proof. The present embodiment adopts a ferrolon heater for electroplating purpose.

Keywords:

Latest News

- Resistor's role in measuring and correcting LED,,,

- Single through-hole resistors' characteristics ,,,

- Why shunt resistors for current sense applicati,,,

- Metal-film resistors with small size, high resi,,,

- 36W High-Current Shunt Resistors MMS8420,,,

- 1W Surface Mount Resistor MPR1206,,,

- An Overview of Microhm Electronics' Resistor Pr,,,

- More anti-sulfur resistors used in harsh envir,,,

- Resistance changes with temperature,,,

- 140W TO247 High Power Heatsinkable Resistor,,,

- MMS5930 is ideal for current sensing in industr,,,

- Shunt resistors selection for engineers' design,,,

- Considerations for choosing precision resistors,,,

- Ceramic Encased Cement Resistors NWH Series for,,,

- Resistors for Passive Balancing in Battery-Pow,,,

Hot Articles

- Microhm will take part in 10th Automotive World,,,

- Thanks for Visiting Microhm's Booth E5-5706 in ,,,

- Resistors in Short Supply: Blame Cars,,,

- New lunch: High Power Precision Shunt Resistor,,,,

- How to Test a Resistor,,,

- Innovative Technology, Future Electric: Electri,,,

- What is Precision Resistors?,,,

- SMD Resistors Sizes and Packages,,,

- The Construction and Features of Metal Film Res,,,

- What is a TO-220 Resisor?,,,

- Hot Selling Products: Precision Shunt Resistors,,,

- How to Calculate the Equivalent Resistance Valu,,,

- What is a Fixed Resistor?,,,

- Resistors in LED Circuits,,,

- Resistors Types and Materials Overview,,,

Resistance applications

- Industrial Roberts Applied to Solar Photovoltai,,,

- Miniature future for passive electronic compone,,,

- Heater Blower Motor Resistor in Air Conditioner,,,

- Carbon Film Resistors' Features and Application,,,

- The Four Important Functions of Alloy Resistors,,,

- Surface Mount Resistor's Size and Package ,,,

- Why Zero-Ohm Resistors?,,,

- BMS for New Energy Vehicle,,,

- Precision Resistors' Construction and TCR,,,

- The Measurement Accuracy of Automotive Shunt is,,,

- Select the Right Resistor for Harmonic Filterin,,,

- The Main Application for High Precision and Low,,,

- Difference Between High Precision Resistors and,,,

- Shunt Resistor MMS8420 for High Current Stable ,,,

- Urbanization Development Bringing the Transform,,,