Position:Home » Technical Articles

What is the Difference between Film - Type Power Resistance and Wire - Wound Power Resistance?

Writer:Microhm Page View:Date:2019-04-08

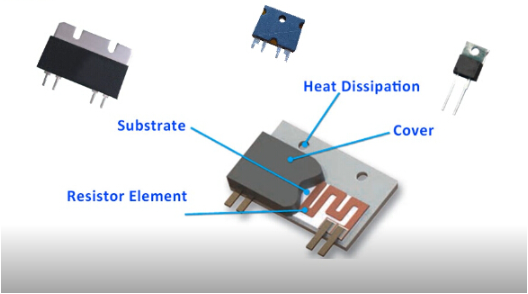

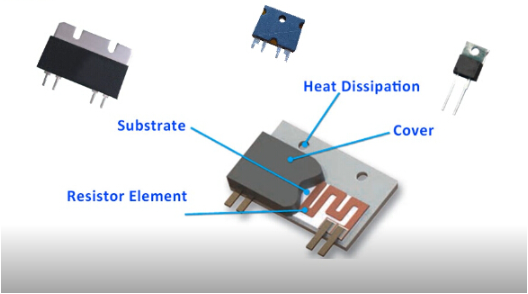

The film-type power resistance and the wire-wound power resistance are both important components of the power resistance. Usually, the film-type power resistance adopts the high-temperature vacuum coating technology to tightly attach the resistance material to the surface of the ceramic rod to form a protective film, and then add the appropriate joint to cut. And the surface is coated with epoxy resin seal protection. Its surface is often coated with green protective paint. The thickness of the film power resistance determines the value of the resistance. The resistance is usually controlled by controlling the thickness and groove of the film. The compound is thermally decomposed on the substrate in a vacuum. In general, most of these resistors are in plug-in resistor packaging, but they are also different.

At present, aluminum oxide or aluminum nitride substrate printed thick film resistance slurry is the most commonly used to produce film power resistance. The film type power resistance is wider than the resistance range of the resistive film resistor. In addition, film-type power resistors can provide high power density, no inductive and no capacitance, so they are very suitable for good heat dissipation conditions with limited space.

At present, aluminum oxide or aluminum nitride substrate printed thick film resistance slurry is the most commonly used to produce film power resistance. The film type power resistance is wider than the resistance range of the resistive film resistor. In addition, film-type power resistors can provide high power density, no inductive and no capacitance, so they are very suitable for good heat dissipation conditions with limited space.

Either type of resistor has its own disadvantage, and the film-type power resistor is without exception. Due to the high requirements for heat dissipation, it is necessary to add a suitable heat sink to reach the rated power, which is relatively cost-effective. In addition, the overload capacity of the film-type power resistor is limited, and can be easily damaged in the high-energy pulse application such as a discharge circuit, and the stability of the film-type power resistor is relatively low. However, for high-precision film-type power resistance, these indexes are improved, especially when the power density is greatly improved, the defects can be effectively avoided.

In addition, the wire wound power resistor has great advantages. Compared with the film resistance, the process of winding power resistance is simpler, price is cheaper, and the power is bigger. On the other hand, the wire wound resistor in the market are cumbersome, poor reliability, and inductive. These factors are the biggest challenge to the winding power resistors.

In addition, the wire wound power resistor has great advantages. Compared with the film resistance, the process of winding power resistance is simpler, price is cheaper, and the power is bigger. On the other hand, the wire wound resistor in the market are cumbersome, poor reliability, and inductive. These factors are the biggest challenge to the winding power resistors.

Either type of resistor has its own disadvantage, and the film-type power resistor is without exception. Due to the high requirements for heat dissipation, it is necessary to add a suitable heat sink to reach the rated power, which is relatively cost-effective. In addition, the overload capacity of the film-type power resistor is limited, and can be easily damaged in the high-energy pulse application such as a discharge circuit, and the stability of the film-type power resistor is relatively low. However, for high-precision film-type power resistance, these indexes are improved, especially when the power density is greatly improved, the defects can be effectively avoided.

Keywords:

Latest News

- Resistor's role in measuring and correcting LED,,,

- Single through-hole resistors' characteristics ,,,

- Why shunt resistors for current sense applicati,,,

- Metal-film resistors with small size, high resi,,,

- 36W High-Current Shunt Resistors MMS8420,,,

- 1W Surface Mount Resistor MPR1206,,,

- An Overview of Microhm Electronics' Resistor Pr,,,

- More anti-sulfur resistors used in harsh envir,,,

- Resistance changes with temperature,,,

- 140W TO247 High Power Heatsinkable Resistor,,,

- MMS5930 is ideal for current sensing in industr,,,

- Shunt resistors selection for engineers' design,,,

- Considerations for choosing precision resistors,,,

- Ceramic Encased Cement Resistors NWH Series for,,,

- Resistors for Passive Balancing in Battery-Pow,,,

Hot Articles

- Microhm will take part in 10th Automotive World,,,

- Thanks for Visiting Microhm's Booth E5-5706 in ,,,

- Resistors in Short Supply: Blame Cars,,,

- New lunch: High Power Precision Shunt Resistor,,,,

- How to Test a Resistor,,,

- Innovative Technology, Future Electric: Electri,,,

- What is Precision Resistors?,,,

- SMD Resistors Sizes and Packages,,,

- The Construction and Features of Metal Film Res,,,

- What is a TO-220 Resisor?,,,

- Hot Selling Products: Precision Shunt Resistors,,,

- How to Calculate the Equivalent Resistance Valu,,,

- What is a Fixed Resistor?,,,

- Resistors in LED Circuits,,,

- Resistors Types and Materials Overview,,,

Resistance applications

- Heater Blower Motor Resistor in Air Conditioner,,,

- Shunt Resistor MMS8420 for High Current Stable ,,,

- The Measurement Accuracy of Automotive Shunt is,,,

- Industrial Roberts Applied to Solar Photovoltai,,,

- The Four Important Functions of Alloy Resistors,,,

- Surface Mount Resistor's Size and Package ,,,

- The Main Application for High Precision and Low,,,

- Urbanization Development Bringing the Transform,,,

- BMS for New Energy Vehicle,,,

- Why Zero-Ohm Resistors?,,,

- Carbon Film Resistors' Features and Application,,,

- Precision Resistors' Construction and TCR,,,

- Difference Between High Precision Resistors and,,,

- Select the Right Resistor for Harmonic Filterin,,,

- Miniature future for passive electronic compone,,,