Position:Home » Technical Articles

The Main Difference between Noninductive Resistor and Wirewound Resistor

Writer:Microhm Page View:Date:2019-02-26

Non-inductive resistor, only relatively speaking, is mainly to meet the needs of intermediate-frequency circuits and high-frequency circuits. The inductance of wire-wound resistance is reduced by selecting non-magnetic material and special winding method, which is close to ideal pure resistance. There are many relationships between noninductive resistor and wire-wound resistor. Many noninductive resistors are wire-wound ones. In the strict sense, wire-wound resistors are actually inductive resistors.

There are usually several methods in the production of noninductive resistors, and their fabrication is very much the same as that of wire-wound resistors. The actual production of noninductive resistors is usually carried out in the following ways.

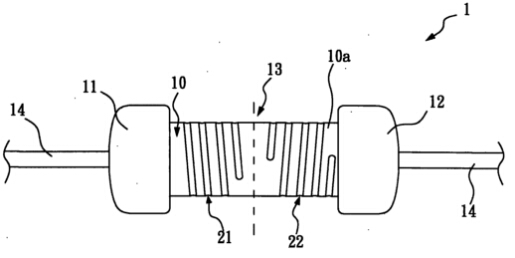

Two-wire parallel method is used by many resistance manufactures. It uses two resistance wires in the ceramic tube or resistance bracket to double-wire and winding, each segment winds half of the resistance value, connecting two resistance wires at one end, and the other two ends are separated as the lead-out end for noninductive resistors. The non-inductive resistance made in this way is better, and the inductance is very small, but there are several problems in the process. One is that two resistance wires need to be insulated from each other. Secondly, the insulation between turns is required because lead-out at the same end. So it is only suitable for making low voltage and low resistors in practical application.

The non-inductive resistor uses a ceramic tube or a resistor bracket to roll around a resistance of half first and then reverse, so that the magnetic field produced by the resistance coil in front of half is in theory opposite to that produced by a resistance coil in the second half and can counteract each other, make non-inductive resistance. However, it is proved in practice that this winding method is not very effective because of the difference of the position of the two resistance coils. The inductance reduction is not obvious, so the non-inductive resistance made is generally suitable for the wire-wound resistance with low resistance value in the circuit below 400HZ.

Two-wire parallel method is used by many resistance manufactures. It uses two resistance wires in the ceramic tube or resistance bracket to double-wire and winding, each segment winds half of the resistance value, connecting two resistance wires at one end, and the other two ends are separated as the lead-out end for noninductive resistors. The non-inductive resistance made in this way is better, and the inductance is very small, but there are several problems in the process. One is that two resistance wires need to be insulated from each other. Secondly, the insulation between turns is required because lead-out at the same end. So it is only suitable for making low voltage and low resistors in practical application.

The non-inductive resistor uses a ceramic tube or a resistor bracket to roll around a resistance of half first and then reverse, so that the magnetic field produced by the resistance coil in front of half is in theory opposite to that produced by a resistance coil in the second half and can counteract each other, make non-inductive resistance. However, it is proved in practice that this winding method is not very effective because of the difference of the position of the two resistance coils. The inductance reduction is not obvious, so the non-inductive resistance made is generally suitable for the wire-wound resistance with low resistance value in the circuit below 400HZ.

In addition to the above two fabrication methods, the non-inductive resistor can also use the cross-winding method, which can make the wire-wound resistance with high resistance value, high-quality. The performance is relatively stable. It is used in many electronic products.

It takes a lot of work to get a qualified resistor. High-quality non-inductive resistance is better to use precision film resistor, which can effectively achieve low residual inductance. For lines larger than 1kHz, its distributed inductance and distributed capacitance can not be ignored sometimes.

Keywords:Wirewound Re

Latest News

- Resistor's role in measuring and correcting LED,,,

- Single through-hole resistors' characteristics ,,,

- Why shunt resistors for current sense applicati,,,

- Metal-film resistors with small size, high resi,,,

- 36W High-Current Shunt Resistors MMS8420,,,

- 1W Surface Mount Resistor MPR1206,,,

- An Overview of Microhm Electronics' Resistor Pr,,,

- More anti-sulfur resistors used in harsh envir,,,

- Resistance changes with temperature,,,

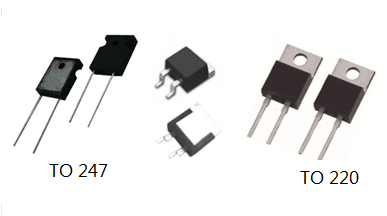

- 140W TO247 High Power Heatsinkable Resistor,,,

- MMS5930 is ideal for current sensing in industr,,,

- Shunt resistors selection for engineers' design,,,

- Considerations for choosing precision resistors,,,

- Ceramic Encased Cement Resistors NWH Series for,,,

- Resistors for Passive Balancing in Battery-Pow,,,

Hot Articles

- Microhm will take part in 10th Automotive World,,,

- Thanks for Visiting Microhm's Booth E5-5706 in ,,,

- Resistors in Short Supply: Blame Cars,,,

- New lunch: High Power Precision Shunt Resistor,,,,

- How to Test a Resistor,,,

- Innovative Technology, Future Electric: Electri,,,

- What is Precision Resistors?,,,

- SMD Resistors Sizes and Packages,,,

- The Construction and Features of Metal Film Res,,,

- What is a TO-220 Resisor?,,,

- Hot Selling Products: Precision Shunt Resistors,,,

- How to Calculate the Equivalent Resistance Valu,,,

- What is a Fixed Resistor?,,,

- Resistors in LED Circuits,,,

- Resistors Types and Materials Overview,,,

Resistance applications

- Industrial Roberts Applied to Solar Photovoltai,,,

- Precision Resistors' Construction and TCR,,,

- Shunt Resistor MMS8420 for High Current Stable ,,,

- Carbon Film Resistors' Features and Application,,,

- The Main Application for High Precision and Low,,,

- Heater Blower Motor Resistor in Air Conditioner,,,

- BMS for New Energy Vehicle,,,

- The Four Important Functions of Alloy Resistors,,,

- Surface Mount Resistor's Size and Package ,,,

- The Measurement Accuracy of Automotive Shunt is,,,

- Miniature future for passive electronic compone,,,

- Difference Between High Precision Resistors and,,,

- Why Zero-Ohm Resistors?,,,

- Select the Right Resistor for Harmonic Filterin,,,

- Urbanization Development Bringing the Transform,,,