Position:Home » Technical Articles

Selecting Right Resistors for Preamp, Amplifier and Other High-End Audio Applications

Writer:Microhm Page View:Date:2019-08-20

In high-end audio equipment, careful selection of resistors is one of the best ways to avoid or minimize noise and distortion in the signal path. Noise is an unwanted wide spectrum signal that may be superimposed on any useful signal, including DC. Resistors, like other passive components, are noise sources to various degrees, depending upon resistance value, temperature, applied voltage, and resistor type. Microhm Electronics manufactures varied resistors, including below mentioned thin film resistors, thick film resistors, metal foil resistors, wire wound resistors and more.

Many experiments have been done to show why some resistors are "noisier" than others. But the only test that audio experts and audiophiles have agreed on is comparing the level of fidelity that results when different resistor technologies are used in actual audio systems.

Overall resistor noise has several components. The most relevant for audio applications are thermal noise and current noise.Thermal noise is notable for being independent of the resistive material. In fact, the thermal noise level is the same for any type of resistor provided the resistances and temperatures are the same.

Current noise, on the other hand, has a direct relationship to the type of resistive material. The spectral density of voltage of current noise SE is found experimentally to be directly proportional to the square of DC voltage drop U across the resistor and inversely proportional to the frequency.

Resistors based on composition resistive materials such as carbon and thick film have the highest level of current noise. Why? Because of the significant non-homogeneity of these resistive element materials. The conduction path in composite materials is formed by the conductive particles touching one another in an isolative matrix. Non-stable contacts in these "touching sites" generate noise when electrical current runs across them.

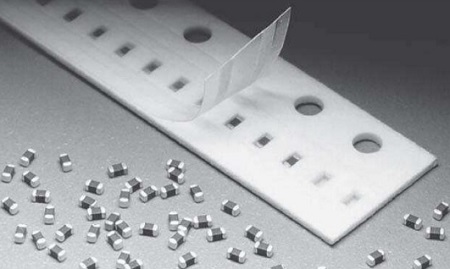

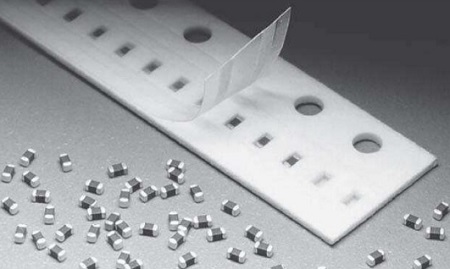

Thin-film resistors have a considerably more homogeneous structure and consequently are less noisy. Thin films are deposed using evaporating or sputtering of resistive material (for example tantalum nitride TaN, silicon chromium SiCr, and nickel chromium NiCr) onto a ceramic substrate. Microhm's NAP series and NR series are thin films resistors. The thickness of the layer varies typically from 10 to 500 angstroms depending on the resistance value. The noise in thin films results from the occlusions, surface imperfections, and non-uniform depositions which are more significant when the film is thinner. That is why the thicker the resistive film, the lower the resistance value and thus the lower the noise level. Users can find full range of metal foil resitors in Microhm Electronics, like NMS2818, NMS4527, MVR2321-4.

The lowest noise level is observed in resistors with bulk metal resistive elements: foil and wirewound. Wire is made of metal alloys similar to foil material, but additional noise may come from the junction of the fine wire of the resistive element and the comparatively coarse resistor terminals. In foil resistors, the terminals and the resistive element are parts of the same piece of the foil, so this problem is avoided.

But the major objection to wirewound resistors is their inductance, which results in chopping the signal peaks1, and the significant dependence of resistor impedance on signal frequency. In addition, special attention must be paid to the following effects associated with reactance of wirewound resistors.

Many experiments have been done to show why some resistors are "noisier" than others. But the only test that audio experts and audiophiles have agreed on is comparing the level of fidelity that results when different resistor technologies are used in actual audio systems.

Overall resistor noise has several components. The most relevant for audio applications are thermal noise and current noise.Thermal noise is notable for being independent of the resistive material. In fact, the thermal noise level is the same for any type of resistor provided the resistances and temperatures are the same.

Current noise, on the other hand, has a direct relationship to the type of resistive material. The spectral density of voltage of current noise SE is found experimentally to be directly proportional to the square of DC voltage drop U across the resistor and inversely proportional to the frequency.

Resistors based on composition resistive materials such as carbon and thick film have the highest level of current noise. Why? Because of the significant non-homogeneity of these resistive element materials. The conduction path in composite materials is formed by the conductive particles touching one another in an isolative matrix. Non-stable contacts in these "touching sites" generate noise when electrical current runs across them.

Thin-film resistors have a considerably more homogeneous structure and consequently are less noisy. Thin films are deposed using evaporating or sputtering of resistive material (for example tantalum nitride TaN, silicon chromium SiCr, and nickel chromium NiCr) onto a ceramic substrate. Microhm's NAP series and NR series are thin films resistors. The thickness of the layer varies typically from 10 to 500 angstroms depending on the resistance value. The noise in thin films results from the occlusions, surface imperfections, and non-uniform depositions which are more significant when the film is thinner. That is why the thicker the resistive film, the lower the resistance value and thus the lower the noise level. Users can find full range of metal foil resitors in Microhm Electronics, like NMS2818, NMS4527, MVR2321-4.

The lowest noise level is observed in resistors with bulk metal resistive elements: foil and wirewound. Wire is made of metal alloys similar to foil material, but additional noise may come from the junction of the fine wire of the resistive element and the comparatively coarse resistor terminals. In foil resistors, the terminals and the resistive element are parts of the same piece of the foil, so this problem is avoided.

But the major objection to wirewound resistors is their inductance, which results in chopping the signal peaks1, and the significant dependence of resistor impedance on signal frequency. In addition, special attention must be paid to the following effects associated with reactance of wirewound resistors.

Latest News

- Resistor's role in measuring and correcting LED,,,

- Single through-hole resistors' characteristics ,,,

- Why shunt resistors for current sense applicati,,,

- Metal-film resistors with small size, high resi,,,

- 36W High-Current Shunt Resistors MMS8420,,,

- 1W Surface Mount Resistor MPR1206,,,

- An Overview of Microhm Electronics' Resistor Pr,,,

- More anti-sulfur resistors used in harsh envir,,,

- Resistance changes with temperature,,,

- 140W TO247 High Power Heatsinkable Resistor,,,

- MMS5930 is ideal for current sensing in industr,,,

- Shunt resistors selection for engineers' design,,,

- Considerations for choosing precision resistors,,,

- Ceramic Encased Cement Resistors NWH Series for,,,

- Resistors for Passive Balancing in Battery-Pow,,,

Hot Articles

- Microhm will take part in 10th Automotive World,,,

- Thanks for Visiting Microhm's Booth E5-5706 in ,,,

- Resistors in Short Supply: Blame Cars,,,

- New lunch: High Power Precision Shunt Resistor,,,,

- How to Test a Resistor,,,

- Innovative Technology, Future Electric: Electri,,,

- What is Precision Resistors?,,,

- SMD Resistors Sizes and Packages,,,

- The Construction and Features of Metal Film Res,,,

- What is a TO-220 Resisor?,,,

- Hot Selling Products: Precision Shunt Resistors,,,

- How to Calculate the Equivalent Resistance Valu,,,

- What is a Fixed Resistor?,,,

- Resistors in LED Circuits,,,

- Resistors Types and Materials Overview,,,

Resistance applications

- Heater Blower Motor Resistor in Air Conditioner,,,

- Surface Mount Resistor's Size and Package ,,,

- Precision Resistors' Construction and TCR,,,

- Industrial Roberts Applied to Solar Photovoltai,,,

- Shunt Resistor MMS8420 for High Current Stable ,,,

- The Main Application for High Precision and Low,,,

- The Measurement Accuracy of Automotive Shunt is,,,

- Carbon Film Resistors' Features and Application,,,

- Difference Between High Precision Resistors and,,,

- BMS for New Energy Vehicle,,,

- Select the Right Resistor for Harmonic Filterin,,,

- The Four Important Functions of Alloy Resistors,,,

- Miniature future for passive electronic compone,,,

- Urbanization Development Bringing the Transform,,,

- Why Zero-Ohm Resistors?,,,