Position:Home » Industry News

The Next Generation in Passive Electronic Components

Writer:万利隆电子 Page View:Date:2022-05-07

Passive components hold an important key to the future of how technology will improve while becoming smaller. In the past, design engineers looked strictly at the Bill of Materials to produce the “black box.” And were always distracted by the expensive silicon, and noted passives, only because they appeared far, far down the cost list, at the end.

Smaller case size passive components are important developments in helping reduce the physical size of the electronic goods into which they are sold. Those products that have had the greatest impact on driving the development for smaller case size capacitors, resistors and inductors include smartphones, laptop computers, personal digital assistants, digital still and video cameras; and flat panel displays.

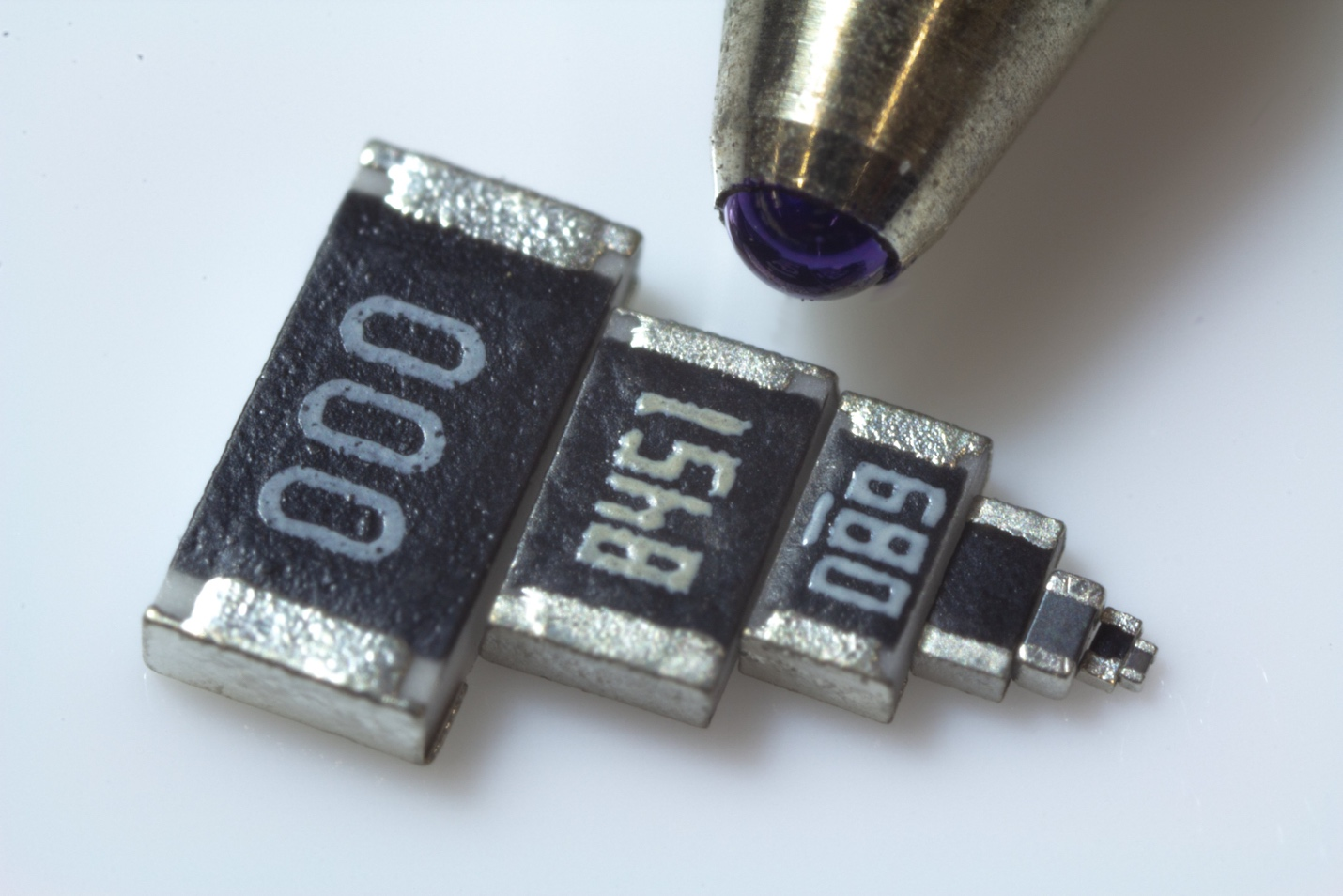

In ceramic capacitors, with emphasis on MLCCs, miniaturization has been dramatic, with global demand switching from the larger 0805 case size parts to the smaller 0603 and 0402 case size parts, and then dropping down to the astonishing 0201 (EIA) case size in 2003, and by 2016 the 01005 had created a firm foothold as the next generation in extremely small electronic components. And now the trend moves forward with the introduction of the 008004 in MLCC thick film chip resistor and in ceramic chip inductor (very cutting edge, very state of the art). But as the discussions around the conference rooms for many of the major brand name OEMs who dominate the high-tech economy, the goal has to be to be able to produce an entire power amplifier or communication module in a 0201 case size. To achieve that goal in the future, to drive the Internet of Everything into the granularity of human existence, the passive components in the design need to provide their function but be invisible, and be as exactly precise in their performance as possible. To achieve that goal, major design houses will have to extend the palette of the materials that they work with; a more expanded view of the periodic table; and expand the processing capabilities of the machines they use to build the products of the future.

Many companies have moved the technology forward by constantly being a step ahead in MLCC and chip inductor miniaturization. The materials engineering and process control required to successfully produce a 008004 EIA case size component is an enabling technology because they the consistent performance of the components gives a greater lot-to-lot consistency of quality for the module manufacturers. But the discussions always go to the point that at 008004 the component is hardly visible to the eye. This is exactly what the more expensive processes of module manufacturers wanted, but they also know at a certain point, the ability to produce components in a traditional sense will go from individual components to sputtering and etching and the use of semiconductor equipment to process important circuit functions once accomplished by individual discrete components.

The impact of component-modularization could be as great as the recent movement of manufacturing away from OEMs to the CEMs. Component modularization offers component vendors substantial value-added opportunities. As pre-fabricated modules incorporate increasingly larger percentages of passive component circuitry module vendors will take some power away from the mass assembly houses in the interest of increasing the throughput of manufacturing. Microhm Electronics Ltd, believed that R&D investment is the survival Key of technology industry.

Keywords:

Latest News

- Precision Resistors in Autonomous Driving,,,

- Perfect Inflation Storm, COVID lockdown + Ukrai,,,

- The Next Generation in Passive Electronic Compo,,,

- Ne Shortage Trigger Resistor & Chip Industr,,,

- USD 2.96 Billion Growth in Thick Film Resistor ,,,

- Resistor Markets Tighten as Rh Price Skyrocket,,,

- The 5G Materials Battle: Sub-6 GHz vs mmWave,,,

- GREETINGS TO THE YEAR OF TIGER 2022,,,

- Electronic Resistor supply chain 2021 under COV,,,

- New Year Greetings,,,

- SEASON'S GREETINGS,,,

- Microhm electronic high precision metal foil re,,,

- Resistor's role in measuring and correcting LED,,,

- Single through-hole resistors' characteristics ,,,

- Why shunt resistors for current sense applicati,,,

Hot Articles

- Microhm will take part in 10th Automotive World,,,

- Thanks for Visiting Microhm's Booth E5-5706 in ,,,

- Resistors in Short Supply: Blame Cars,,,

- SMD Resistors Sizes and Packages,,,

- New lunch: High Power Precision Shunt Resistor,,,,

- How to Test a Resistor,,,

- Innovative Technology, Future Electric: Electri,,,

- What is Precision Resistors?,,,

- The Construction and Features of Metal Film Res,,,

- What is a TO-220 Resisor?,,,

- Hot Selling Products: Precision Shunt Resistors,,,

- How to Calculate the Equivalent Resistance Valu,,,

- What is a Fixed Resistor?,,,

- Resistors in LED Circuits,,,

- Precision Resistors in Autonomous Driving,,,

Resistance applications

- Electronica 2018, A Wonderful Review of MICROHM,,,

- How Much Performance Does Engineers Need for Re,,,

- Metal Film Resistors Features,,,

- Resistors' Frequency Response,,,

- Microhm Power Chip Resistor NFC Series,,,

- Precision Metal-Film Resistors MCC Series,,,

- The Application of Sampling Resistor in New Ene,,,

- Thin and Thick Film Resistors' Characteristics ,,,

- Automotive World Japan 2019 will Open Tomorrow,,,,

- NLR Series with Heat Sink Provide Non-Inductive,,,

- How to Reduce Failure Rate of New Energy Vehicl,,,

- Why Precision Resistance Stability is very Impo,,,

- Metal Foil Resistor Characteristics,,,

- Metal Oxide Power Film Resistors NGT Series,,,

- The Technical Problems in the Operation and Mai,,,