Position:Home » Industry News

Precision Wirewound Resistors' Strengths and Weaknesses

Writer:Microhm Page View:Date:2019-08-06

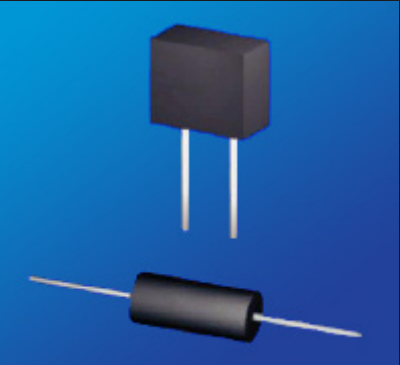

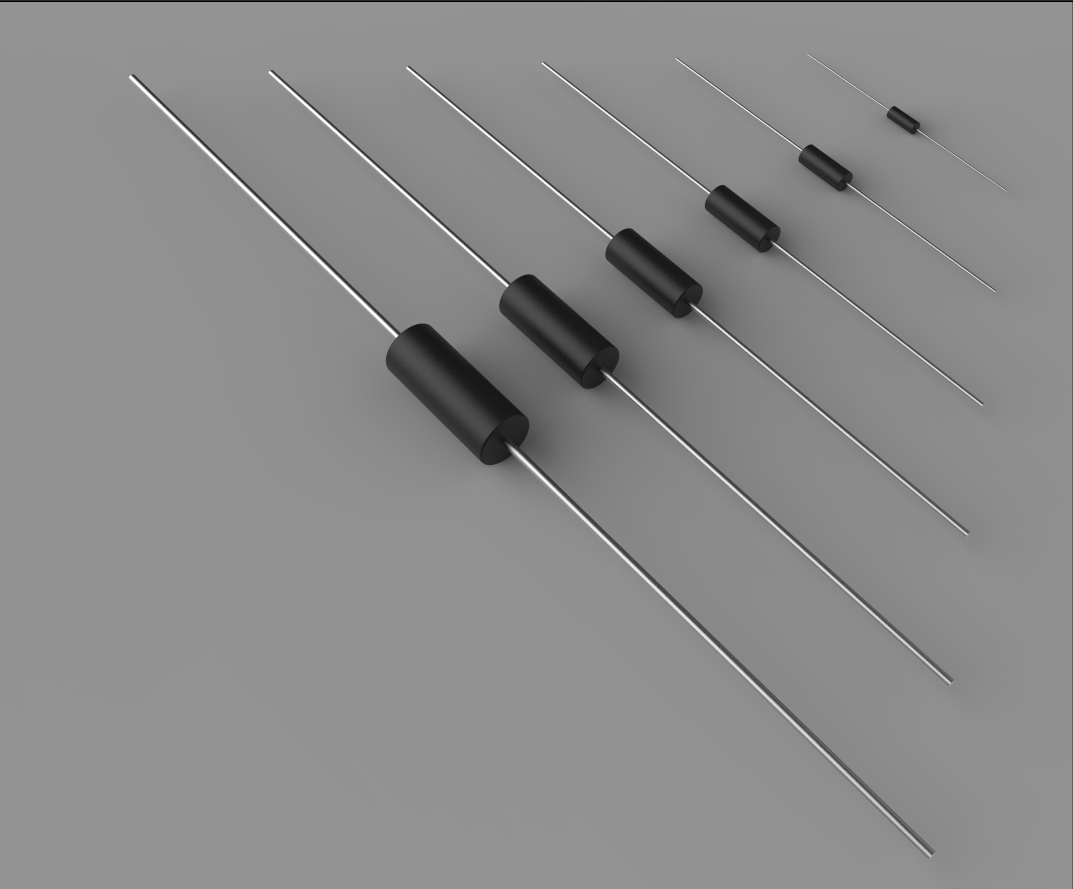

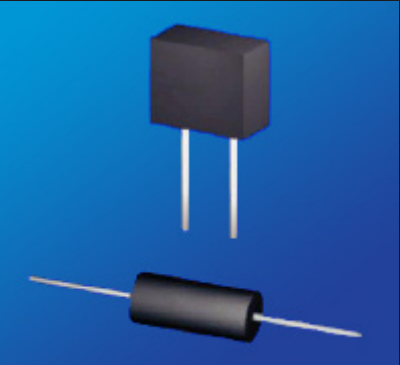

Wirewound resistors, power precision resistors and shunt resistors are composed of Microhm main lineup.The wirewound resistor is usually made by winding insulated resistance wire of a specific diameter around a bobbin. Different wire diameters, lengths, and alloys provide the desired resistance and initial characteristics. Precision wirewound resistors have better ESD stability and lower noise than thin or thick film resistors. Wirewounds also have a lower TCR and better stability.

The initial tolerance of wirewound resistors can be at low as ±0.005%. The TCR, which is the amount of resistance change with each degree Centigrade change in temperature, can be as little as 2 ppm/°C, Microhm NCR series is a typical precision wirewound resistor with ±0.005% tolerance and 2 ppm/°C ; but for low resistance values, wirewounds are generally in the region of 15 ppm/°C to 25 ppm/°C. Thermal noise is low, and TCR tracking to ±1 ppm/°C over a limited temperature range is possible.

Because of their coiled-wire construction, wirewound resistors are inductors, and the proximity of the turns creates intercoil capacitance. To increase the response time in service, special winding techniques may be used to reduce the inductance. Due to the inductance and capacitance inherent in the design, wirewound resistors have poor high-frequency characteristics, particularly above 50 kHz.

It is difficult to make two wirewound resistors that accurately track each other over a specified temperature range when they are of the same nominal resistance value, and especially so when their values are not the same or when they are of different sizes (e.g., to meet different power requirements). The difficulty increases as the divergence of the resistance values increases.

The reason for this disparity is that a 1-kΩ resistor is made with a different diameter, length, and possibly alloy of wire than, for example, a 100-kΩ resistor. Moreover, the core sizes and turns per inch are different — again, mechanical properties affect electrical properties. Since the different values have different thermo-mechanical characteristics, their in-service stabilities vary and designed resistor ratios diverge more through equipment life. The TCR tracking and ratio stability are extremely important in high-precision circuitry.

Wirewound resistors are generally classified as either “power wirewounds” or “precision wirewounds.” Power wirewound resistors are subject to greater changes in service and are not used where precision performance is required; therefore, they are not considered in this discussion.

The initial tolerance of wirewound resistors can be at low as ±0.005%. The TCR, which is the amount of resistance change with each degree Centigrade change in temperature, can be as little as 2 ppm/°C, Microhm NCR series is a typical precision wirewound resistor with ±0.005% tolerance and 2 ppm/°C ; but for low resistance values, wirewounds are generally in the region of 15 ppm/°C to 25 ppm/°C. Thermal noise is low, and TCR tracking to ±1 ppm/°C over a limited temperature range is possible.

Because of their coiled-wire construction, wirewound resistors are inductors, and the proximity of the turns creates intercoil capacitance. To increase the response time in service, special winding techniques may be used to reduce the inductance. Due to the inductance and capacitance inherent in the design, wirewound resistors have poor high-frequency characteristics, particularly above 50 kHz.

Keywords:

Latest News

- Resistor's role in measuring and correcting LED,,,

- Single through-hole resistors' characteristics ,,,

- Why shunt resistors for current sense applicati,,,

- Metal-film resistors with small size, high resi,,,

- 36W High-Current Shunt Resistors MMS8420,,,

- 1W Surface Mount Resistor MPR1206,,,

- An Overview of Microhm Electronics' Resistor Pr,,,

- More anti-sulfur resistors used in harsh envir,,,

- Resistance changes with temperature,,,

- 140W TO247 High Power Heatsinkable Resistor,,,

- MMS5930 is ideal for current sensing in industr,,,

- Shunt resistors selection for engineers' design,,,

- Considerations for choosing precision resistors,,,

- Ceramic Encased Cement Resistors NWH Series for,,,

- Resistors for Passive Balancing in Battery-Pow,,,

Hot Articles

- Microhm will take part in 10th Automotive World,,,

- Thanks for Visiting Microhm's Booth E5-5706 in ,,,

- Resistors in Short Supply: Blame Cars,,,

- New lunch: High Power Precision Shunt Resistor,,,,

- How to Test a Resistor,,,

- Innovative Technology, Future Electric: Electri,,,

- What is Precision Resistors?,,,

- SMD Resistors Sizes and Packages,,,

- The Construction and Features of Metal Film Res,,,

- What is a TO-220 Resisor?,,,

- Hot Selling Products: Precision Shunt Resistors,,,

- How to Calculate the Equivalent Resistance Valu,,,

- What is a Fixed Resistor?,,,

- Resistors in LED Circuits,,,

- Resistors Types and Materials Overview,,,

Resistance applications

- Carbon Film Resistors' Features and Application,,,

- The Measurement Accuracy of Automotive Shunt is,,,

- BMS for New Energy Vehicle,,,

- Heater Blower Motor Resistor in Air Conditioner,,,

- Difference Between High Precision Resistors and,,,

- Surface Mount Resistor's Size and Package ,,,

- Industrial Roberts Applied to Solar Photovoltai,,,

- Miniature future for passive electronic compone,,,

- Why Zero-Ohm Resistors?,,,

- Select the Right Resistor for Harmonic Filterin,,,

- Precision Resistors' Construction and TCR,,,

- The Main Application for High Precision and Low,,,

- The Four Important Functions of Alloy Resistors,,,

- Shunt Resistor MMS8420 for High Current Stable ,,,

- Urbanization Development Bringing the Transform,,,